Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

High Frequency High Speed Copper Clad Laminate CCL Market Size and Share Forecast Outlook 2025 to 2035 The high frequency high speed copper clad laminate CCL market is projected to grow from USD 4.1 billion in 2025 to USD 10.9…

CEM-3 Materials “CEM-3” composite epoxy resin material type 3, is made from epoxy resin, glass cloth, and glass fiber padding. It is a medium-performance material used in the manufacturing of printed circuit boards and is typically considered a cost-effective option suitable for…

FR-1 – phenolic cotton paper, this base material is commonly known as bakelite (more economical than FR-2)FR-2 – phenolic cotton paper,FR-3 – cotton paper, epoxy resinFR-4 – Woven glass, epoxy resinFR-5 – glass cloth, epoxy resinFR-6 – matte glass, polyesterG-10 –…

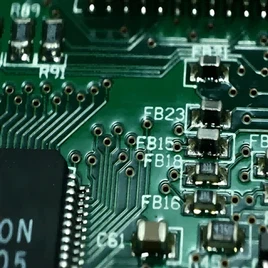

Introduction Copper Clad Laminate (CCL) is the base material of PCB. Bonding a layer of copper foil to a non-conductive substrate, such as fiberglass, plastic, or paper-phenolic made this laminate. The copper layer serves as the conductor for the electrical…

Comprehensive Guide to PCB Via Types A via or vertical interconnect access is a hole in a printed circuit board that is drilled through the board layers and is also comprised of conductive materials like copper filled within to facilitate…

Advantages of copper clad laminate for circuit boards Disadvantages of copper clad laminate for circuit boards

CCL is the core material for the manufacture of printed circuit boards, which is responsible for the three functions of conduction, insulation and support of printed circuit boards. The copper clad laminate has undergone lead-free, halogen-free and thinning, and is…

There are several reasons why you should consider choosing CCL for your PCB projects. A few of them include; Overall, CCL’s high thermal conductivity, excellent electrical insulation, and mechanical strength make them an ideal choice for creating durable and reliable PCBs. Manufacturers…

Choosing CCLs depends on PCB electrical, thermal, and mechanical requirements:

Rigorous standards ensure quality, consistency, and reliability: